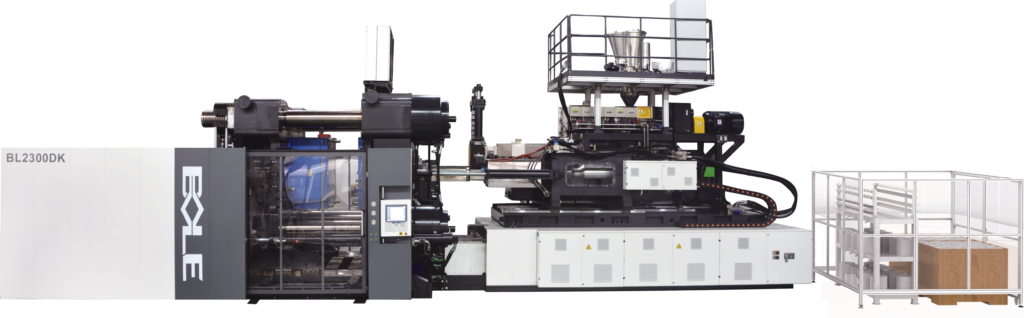

With excellent performance and quality, BOLE MK series multiple IMM will better meet the demand of automobile, household appliances. daily necessities.

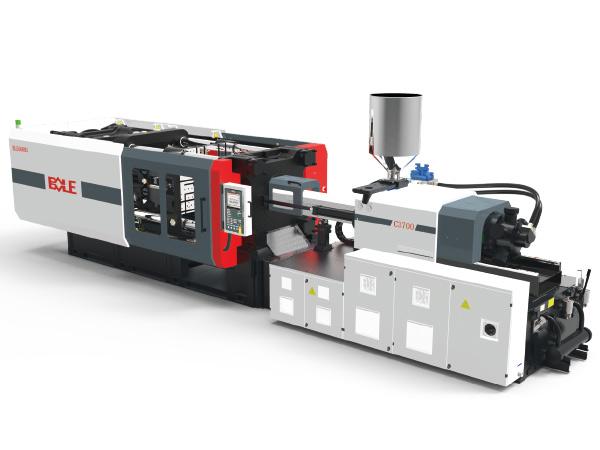

As the edged tool tailored by ‘lightweight of automobile’, ClML carbon fiber product intelligent moulding line combines equipment, tech no Iogyand material and units the “prilling” and ‘injection moulding’ into one, provided fiber reinforced composite moulding technology to help all the customers enhance the core competitiveness.

Bole Europe Technology

ul. Katowicka 72, 41-406 Myslowice POLAND

Tel: +48 32888 76 80

E-mail: office@bole-europe.com

Bole Intelligent GmbH

Merseburg GERMANY

Brandisstraße 4

06217 Merseburg

E-mail: office.de@bole-europe.com