Who we are

as a subsidiary of Chenglu Group

BOLE is a high-tech enterprises that focus on the research, development and manufacture of precision machinery equipment. It adopts the mode of [technology from Germany, made in China", integrates design, manufacture, assembly, testing and sales, and provides complete and professional Injection Moulding devices for customers.

What we offer

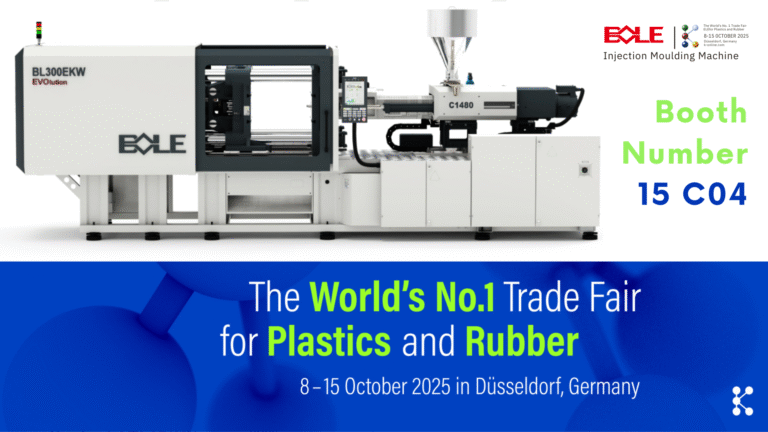

Model No.:EKS Series

- Economy: After sample survey, we conclude BOLE central clamping toggle design can save 2-5% material for 80% of customer’s mould, comparing to traditional dege clamping toggle design.

- Intelligent:Intelligent networking management system March into industry 4.0, opening a new era of intelligent factories. High performance PLC of MMI, which getting information of the robot, mold temperature controller, cooling water, machine accessories etc, realize data interaction, wireless networking management system. Besides, PC or cell phone terminal can always tell machine information, process parameters, operation status, failure situation and product analysis at a glance. Order dispatched by computer, which aims to working efficiency maximization, better product planning and operation control, production efficiency improvement. Meanwhile, we provide EMS data exchange terminal, making it possible to automate the whole line of the factory.

Model No.:DK Series

- Higher productivity

- Dry cycle time equals to European machine

- High overload and bending resisted tie bar. Patent applied

- Symmetric mould open/close design

- Shorter cycle time and morestable

- Higher precision for mould close&open.

- Unique clamping/open cylinder design

- Ensure mould clos&open fast/stable/precise

- Superior controller system

- Excellent machine repeatability

- Advanced modular design

- Quick response solution to customization.

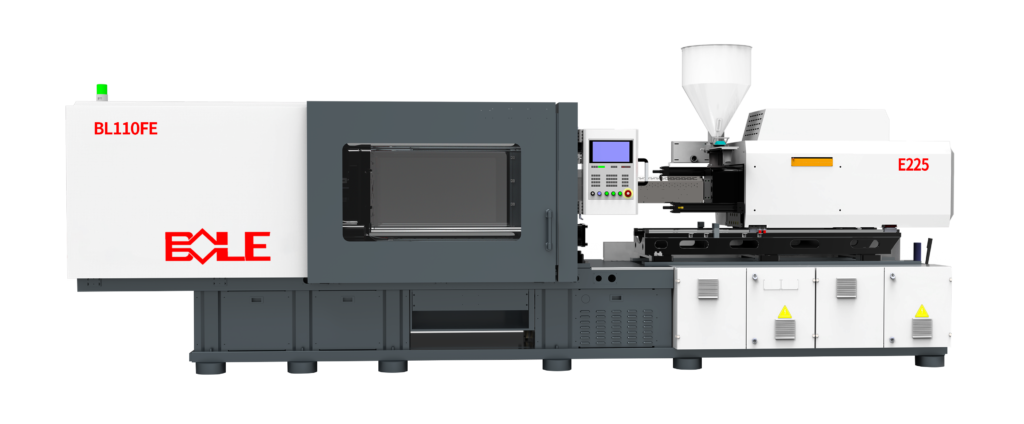

Model No.:FE Series

- Fast &close loop control system excellent repeatability performance.

- Patented central clamping toggle system create uniform clamping force reduces platen deflection.

- Platen drive by servo motor and ball screw.

- German design of plasticizing system increase efficiency of plasticizing over 20%

- Patented encapsulated ball screw.

History

2018 R&D succeeded on well-built MK series.

2017 Joined China plastics processing industry association (CPPIA) and became the governing unit; R&D success on the next generation of EK-S series.

Services

There are a lot of technologies that allow the injection moulding. low has developed the main making innovation and improving the existing solutions. we have given much weight to find defects and find the solution, to start a cycle of continuous improvement.

Latest news