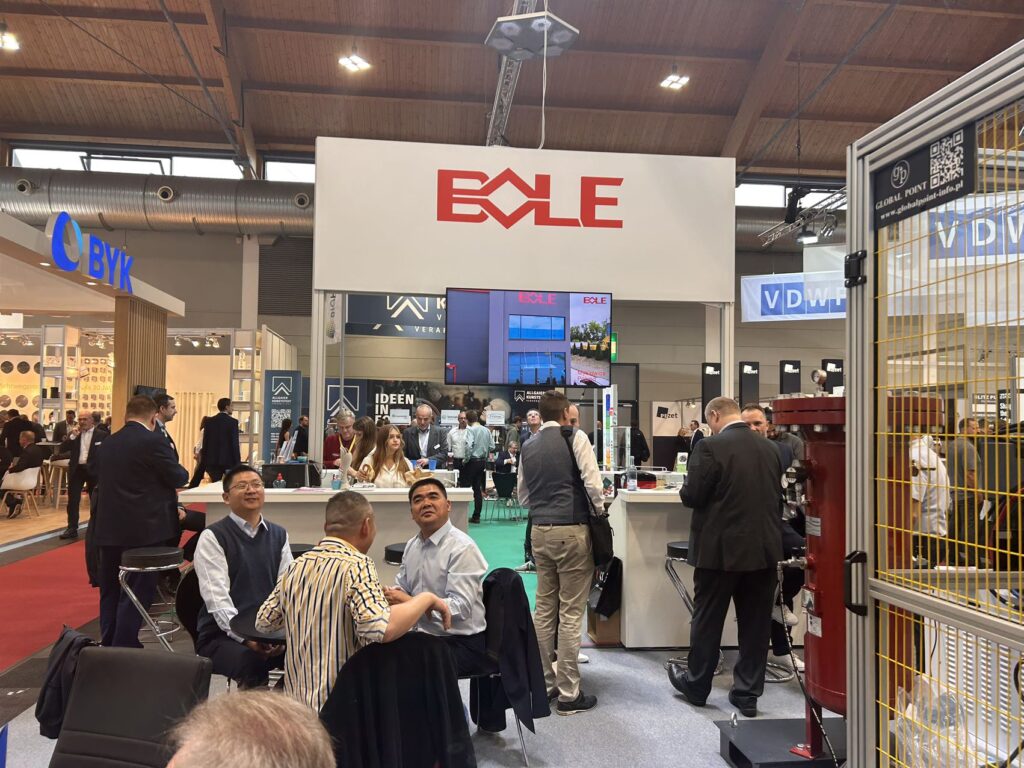

At this year’s PlastpolFair, BOLE Europe received an award for our hasztag#thixomolding technology, which Bole injection Moulding Machine has been intensively developing to achieve better and better results in the field of lightweight materials.

Thixomolding is a technology dedicated to magnesium alloys.

The demand for durable, lightweight products has driven the significant growth of magnesium thixomolding. Its many advantages make it a suitable choice for manufacturing parts found in automotive, consumer products, defense, electronics, handheld devices and sports equipment. As a result, magnesium thixomolding is becoming the favored capability in producing various products in all markets.

Bole, a manufacturer of injection moulding machines, has a significant achievement in the field of thixomolding. The company has a long-standing partnership with Shanghai Jiao Tong University, with which it shares a laboratory. Thanks to its patented technology, the concern is able to produce injection moulding machines with the largest injection and has satisfactory solutions for material modification to achieve adequate anti-corrosion properties, high conductivity and greater strength.

Bole has a range of injection moulding machines designed for tix moulding, with machines up to 4000 tonnes and injection weights up to 17 kg available at the Bole technical centre in China.